Roadwork, mining, quarrying, emergency response? The level of safety required depends on the type of activity involved. For normal work, Protection Class 1 is more than sufficient. This corresponds to 8 mm Hammerglass in the windscreen in order to eliminate the risk of breaking glass. However, if the machine is being used in very tough environments where there is a risk of stones being propelled at high speed, or of explosions occurring, then thicker RABS approved screens will be required all around the cab. Our classifications will help you find the proper protection for work in tough environments.

PROTECTION CLASS 1

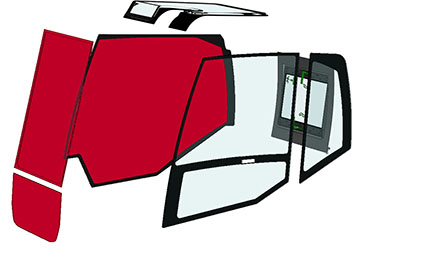

For simpler tasks where there is a risk of stone chippings. Usually required for the windscreen and/or side screen on diggers, wheel loaders, tractors, etc. The original screens are replaced with 8 mm Hammerglass screens, which are fitted in the same way as the original screens.

Protective measure: The original screen is exchanged for a Hammerglass screen

Fitting: The same way as the original screen

Protection specification Front window: 8 mm Hammerglass, split/non-split

Protection specification Boom side window: 8 mm Hammerglass

Accessory: ScreenSaver protective film for the front window

PROTECTION CLASS 2

For tough driver environments where there is a risk of stone chippings, falling stones, and acts of vandalism. The original screens are replaced with 8 mm/12 mm Hammerglass screens, which are fitted in the same way as the original screens.

Protective measure: The original screen is exchanged for a Hammerglass screen

Fitting: The same way as the original screen

Protection specification Front window: 8/12 mm Hammerglass, split/non-split

Protection specification Other screens: 8/12 mm Hammerglass

Accessory: ScreenSaver protective film for the front window

PROTECTION CLASS 3

Where there is a risk of undetonated explosives, risk of explosions from the sides, where quarrying is being carried out or there is a risk of rock fall. The cabin has to offer an escape exit via an escape screen. This has to be reachable by the driver in case of rock slides which close off all other exits. The escape exit also has to be openable from the outside.

Protective measure: All screens are replaced with Hammerglass screens, the front window is fitted in an explosion tested steel frame (RABS approved)

Fitting: The steel frame is fitted on the cabin without interference with the vehicle’s ROPS frame

Protection specification Front window: 12 mm Hammerglass in steel frame

Protection specification Other screens: 12 mm Hammerglass

Accessory: ScreenSaver protective film for the front window, or ScreenSaver protective screen

Explosion tested for maximum safety - this is RABS

RABS is the designation for vehicle screens which indicates that the screens satisfy a combination of international safety standards. Using a RABS-classified solution satisfies personal protection requirements for work involving the risk of undetonated explosives, falling rocks and while quarrying. In order to be marked RABS Approved, the screens must pass all of the following four tests. Hammerglass 12 mm in a steel frame satisfies the RABS requirements.

| R43 | ECE Regulation No.43 (R43). A comprehensive series of tests for vehicle glass, including scratch protection, UV protection and elongation. Compulsory for all vehicles. |

| AXE | Sharp object (EN 356, P8B), a test in which the screen withstands 72 blows from a machine-mounted axe, without the axe penetrating the glass. |

| BLAST | Pressure wave upon detonation (EN 13124-2, EXR 2), a test in which 3 kg (6.6 lbs) TNT are detonated at a distance of 3 meters (9.8 feet) from a screen mounted in an approved steel frame. The screen is mounted in a steel frame so that they cannot be forced into the cab. |

| STONE | Heavy objects at high speed (EN 15152-2), a test in which a 1 kg (2.2 lbs)aluminium projectile is propelled against the screen at a speed of 450 km/h (280 mph) and at an angle of 90 degrees thereto. Equivalent to a large rock propelled at high speed. FOPS Falling Object Protective Structure/FOG Falling Object Guard (EN ISO 3449, ISO 10262, ISO 8083). A test where the system is frozen to -18°C, after which a 227 kg heavy steel cylinder is released from a height of 5.2 meters onto the window (corresponds to a force of 11,600 Joules). |

Health and safety

The requirements on personal safety in work carried out in tough environments are increasing. Among other things, the employer is expected to take all necessary measures to prevent the employee from being exposed to ill health or accidents.

When a hydraulic hammer or other equipment is used for breaking up boulders or solid rock surfaces, measures should be taken to protect those who are working from dust and detonating duds, and to prevent them from being struck by flying rocks.

Measures should be taken to ensure that those who are working on or near crushing equipment are protected from flying rocks and fragments from a detonating dud.

During mechanical loading of blasted rock, measures must be taken to protect the machinery operator against stones, cast from detonating explosives.

Work must be planned and arranged so that it can be carried out in a healthy and safe environment. Adequate protective measures shall be taken against damage due to fall, collapse, fire, explosion, electric current or the like.

The employer should take all necessary precautions to protect workers from being exposed to ill-health or accidents. A starting point shall be that anything that could lead to ill-health or accidents must be modified or replaced to eliminate any risk of ill-health or accidents.

Anyone manufacturing, importing, transferring or letting machinery, implements, protective equipment or any other technical devices must ensure that, when placed on the market, delivered for commissioning or displayed for sale, they offer adequate safety against ill-health and accidents.